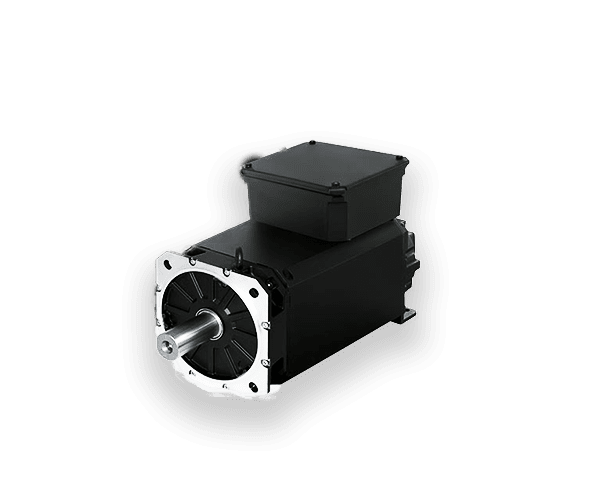

Servo motor repairs

Our repair process

We repair and install servo motors for multiple sectors in the CNC industry. Each servo motor goes into a controlled and rigorous process of inspection, repair and testing. Our certified technicians are always making sure that all components and tolerances respect the different OEM standards. All servo motor repair come with a 1 year 24/7 warranty and a control quality report.

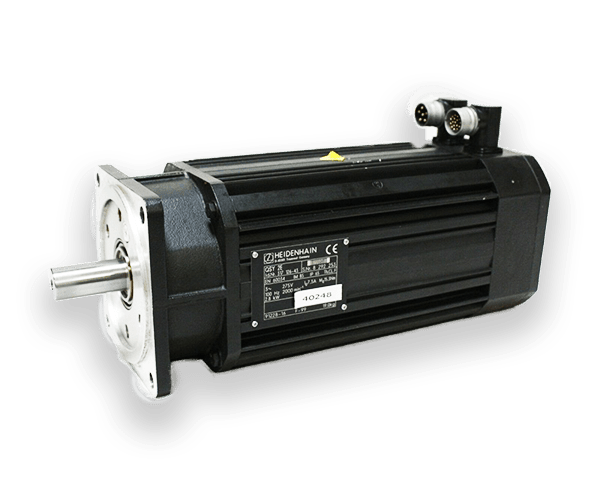

Most common brands repaired

Benefits of our solution

Certified technicians

All our techicians are trained and certified to repair and install servo motors of the woodworking industry.

Servo motors LAB

Entire space dedicated to repair and maintain servo motors.

Machining center

Complete in-house machining center allowing faster and custom solutions with high precision.

Specialized equipment

A temperature controlled, positive pressure assembly room as well as a dynamic balancing bench, CMM and test benches that simulate your CNC.

Our repair process

Preliminary testing

A complete analysis is performed to identify mechanical and electrical problems. The main tests proceeded are the analysis of the encoder, resolver and vibration.

01

Dimensional measuring and electrical testing

Measuring of all precision components performed in out metrology room along with stator testing and electrical components testing.

02

Dissasembly

Once tested, the servo motor is completely disassembled. Furthermore, parts are cleaned and inspected to see if they are damaged. Following, a detailed quote showing technical problems, repair solutions, prices lead time and picture of damaged parts is sent to customer.

03

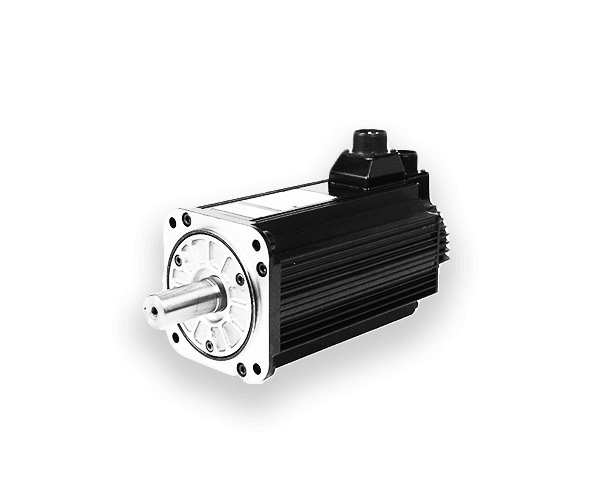

Repairs / Assembly

Multiple solutions can be proceeded on the servo motor such as parts in-house machining, taper grind, dynamic balancing and rewinding of stator. Moreover, contaminated parts can be replaced by new OEM spec ones including bearings, seals, o-rings, encoder, and rotary union, etc. At last, the servo motor is fully assembled.

04

Final Testing

The servo motor is tested on one of our test benches up to full speed making sure temperatures, vibration, and all features are working correctly.

05

Quality Control

The servo motor goes through a quality control where all functionalities and systems are analyzed. After, the spindle is well packed and shipped to the customer place

06

Analysis of the servo motor

During the preliminary testing, each servo motor is analyzed meticulously. Our technicians are doing various tests on it to detect possible problems. Doing that helps us to understand better your spindle condition and to propose you the best solution.

What we are testing

• Verfication of the encoder, resolver or PLG alignment.

• Verification of the temperature at maximum speed.

• Analysis of the vibration level in mm/sec.

• Complete winding system analysis if required.

• Verification of the temperature at maximum speed.

• Complete winding system analysis if required.