Did you know that regularly replacing your vacuum pump’s filters, carbon vanes and grease can extend your pump’s lifecycle by 5 years? It’s true! Vacuum pumps work hard but not smart, they will continue to produce optimal vacuum levels despite a clogged filter, worn out vanes or lack of grease, creating the impression that they are running well. This often causes pump owners to delay part replacement wich unfortunately puts massive stress and wear on other more critical components of the pump. This long-term strain and wear almost ALWAYS shorten the pump’s life cycle and cause the pump to seize up requiring a full pump replacement. Work with us to keep your pump running efficiently.

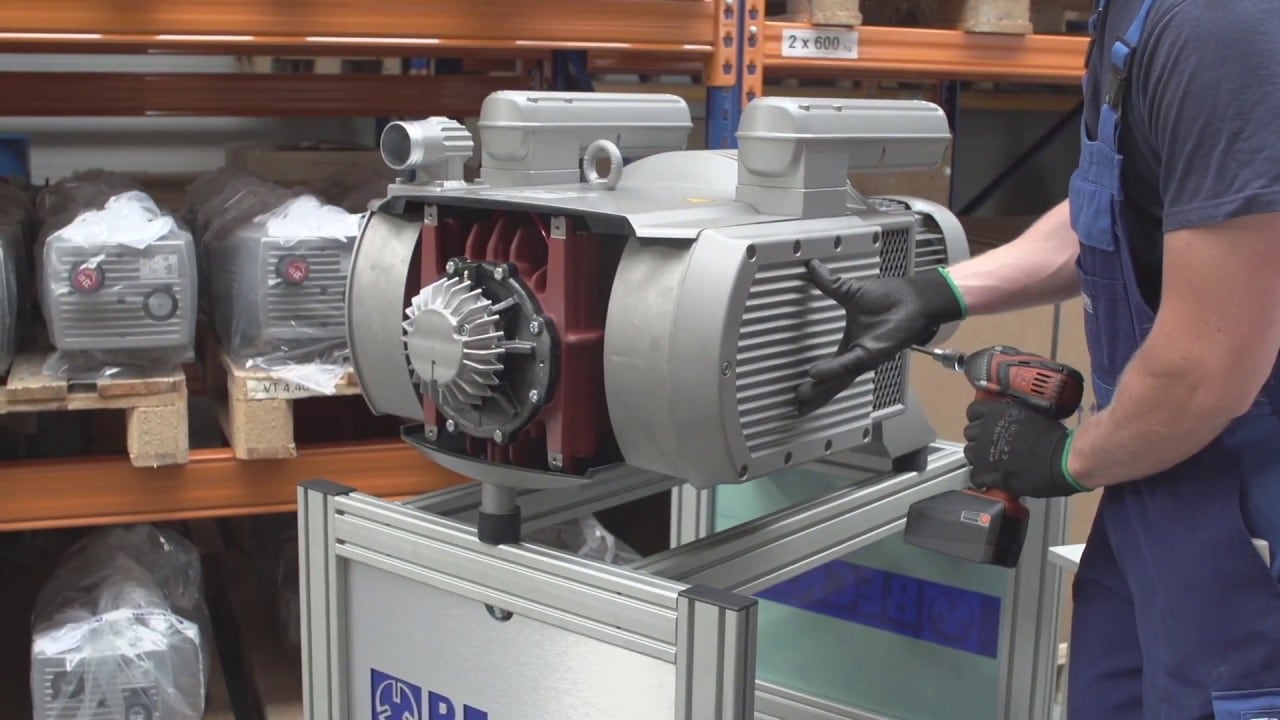

Maintenance Intervals on Becker VTLF 250 non SK Series Pumps

Every 50 hours

Check and clean air intake filters and replace if necessary. Clean more often in dirty environments.

9 months to Yearly

-

Check Vanes for minimum width (41 mm). Replace if necessary.

-

Inspect vanes for improper wear (cupping). Replace if necessary.

-

Inspect Teflon tube seals in end shield. If the hollow center shows through replace them.

-

Examine end shield surface for excessive grease build-up. If evident, check shaft seal. If shaft seal is OK, extend the grease intervals or use less grease. Excessive grease will cause vane failure. Clean end shield with contact cleaner only.

-

Inspect grease in bearing cavity of end shield. If the grease is dried out or burnt in color, bearing needs to be grease more often. Regrease after reassembly if needed.

-

Wipe grease off rotor shaft before re-installing the end shield.

Every 3000 to 4000 Hours

Inspect motor coupling. Replace if necessary.

Grease bearings. 6 or 7 pumps of the grease gun per fitting, making sure grease lines are clear. USE ONLY Amblygon TA 15/2 grease.

BUY YOUR MAINTENANCE KIT TODAY, CONTACT US: