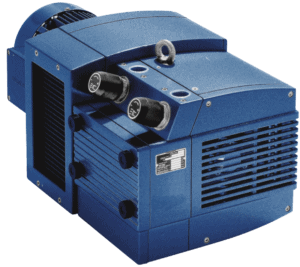

Vacuum pumps

Our partnership

MEC PRECISION is a distributor and service center of BECKER. We have the privilege to access the entire distribution line and own a wide inventory of vacuum pumps. Moreover, we can repair all products. Every repair is done by following the quality standards established by the manufacturer. If you are interested in acquiring or repairing a BECKER vaccum pump, we will be able to help and assist you rapidly.

BECKER

For 135 years, BECKER is a global leading manufacturer of vacuum and pneumatic equipment. It proposes a wide range of vaccum pumps and are available as single component and complete system.Their products are used in multiple industries such as woodworking, plastic and composite, environmental and construction.

Buy your BECKER vacuum pump

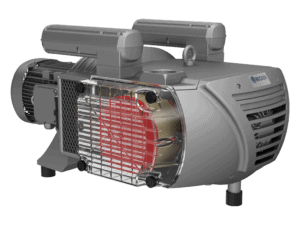

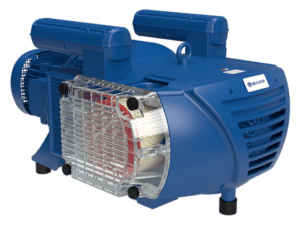

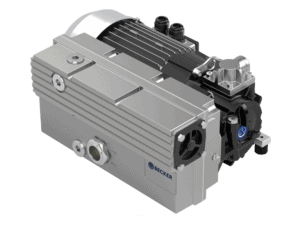

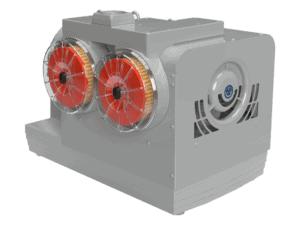

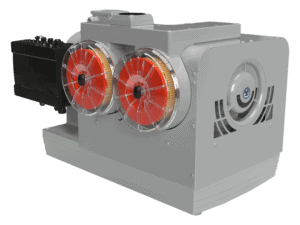

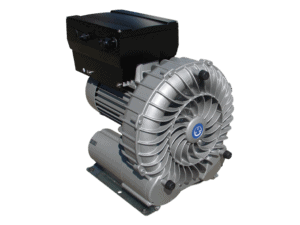

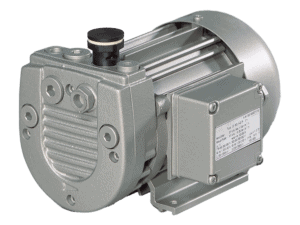

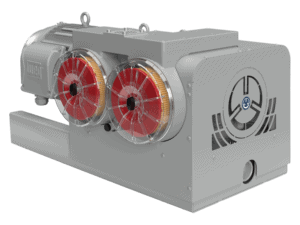

The products

BECKER proposes innovative vacuum pumps, compressors, central vacuum systems, part, accessories and customized vacuum solutions. We can repair and sell any of these technologies!

Get a quoteService center

As a service center, we are able to repair all products of this brand. We have most of the OEM parts in inventory and our technicians are certified BECKER. Every product goes through a rigourous and quality rebuild process. Each one is analysed, fixed and tested by our technicians in a temperature controlled and positive pressure assembly room.

Learn more