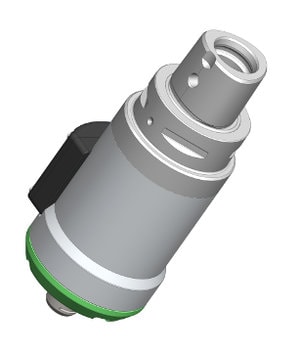

Spindle

speeders

Our partnership

MEC PRECISION is selling COLIBRI spindle speeders. We have the privilege to access the entire distribution line. We own a wide inventory of their products at our factory. If you are interesting in acquiring or replacing a COLIBRI spindle speeder, we will be able to help and assist you rapidly.

COLIBRI

Since 20 years, COLIBRI is a leader in the design and manufacture of high technology of compact, coolant-driven spindles, operating with minimal vibrations and run-out. It is also developping new spindle configurations, applications for the smart way to operate. Their products are mainly used in the metalworking industry.

Buy your COLIBRI spindle

The products

COLIBRI has a wide range of innovative products covering JET HSM or HCP spindle speeders, TR units, display units, tools and accessories. We can repairs and replace any of these technolgies!

Get a quote