Our workshop

Discover MEC's technologies

We have several high precision equipment which help us repair all different models of spindles, servo motors, aggregates, angle heads and vacuum pumps.

WEILER E50 hybride lathe

We acquired the first Weiler E50 in Quebec. This equipment machines, repairs and maintains high precision shafts and bearing housings for CNC products. The lathe provides a turning performance of control and quality during the operations.

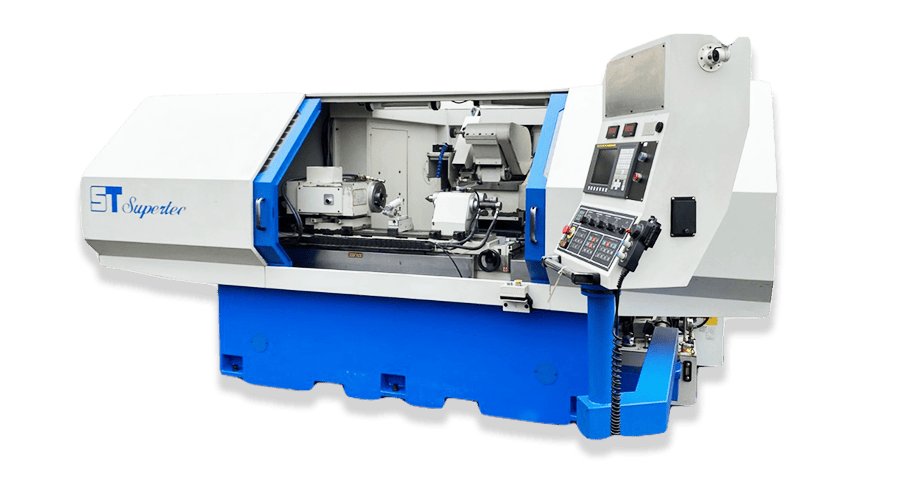

SUPERTEC CNC cylindrical grinder

This machine gives the ability to grind CNC product shafts and bearing housing. Workhead swivels 90°counterclockwise to 30°clockwise for various precision grinding operations. A combination live and dead-type spindle available for quick changeover from center to chuck tasks.

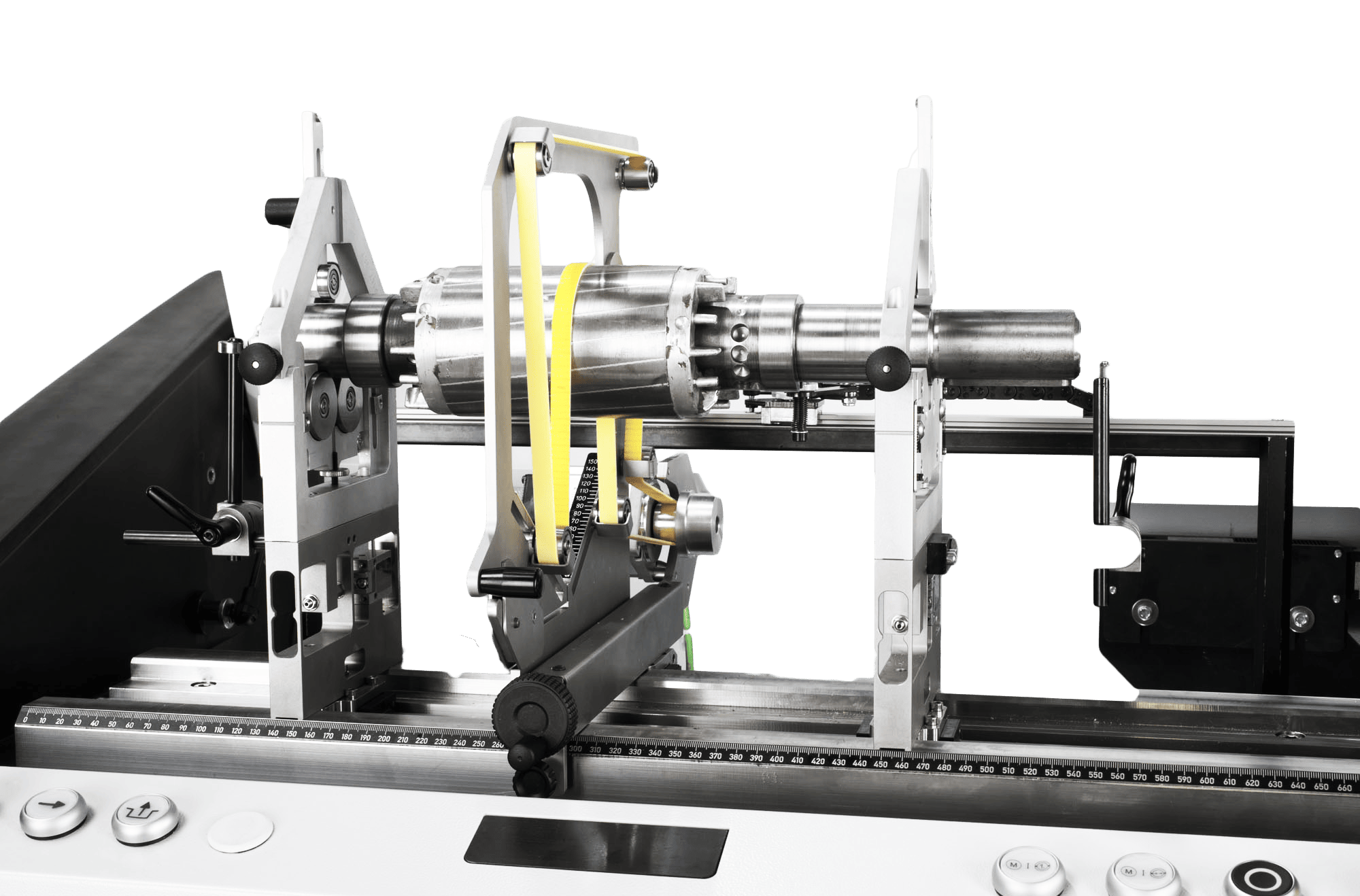

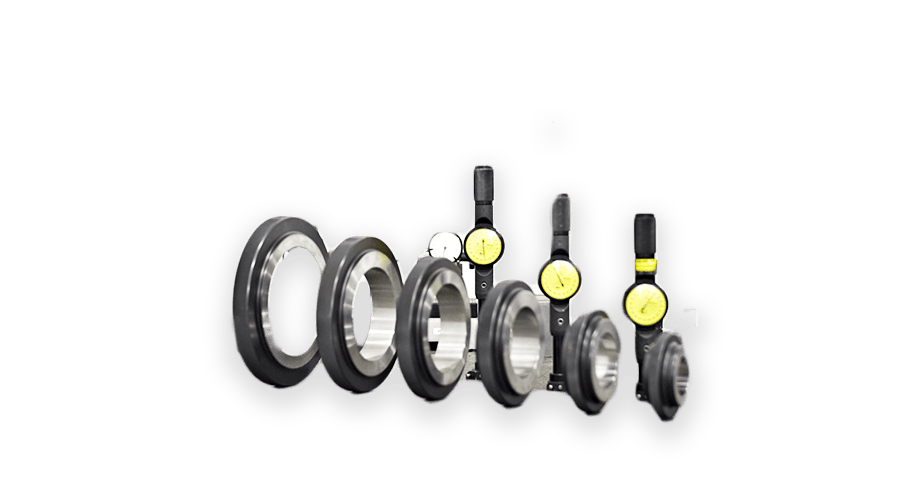

FRANZ KESSLER test bench

This bench tests all KESSLER spindles simulating all the functionalities of a CNC machine. Multiple data in real time are monitored during the process like vibration, temperature and speed.

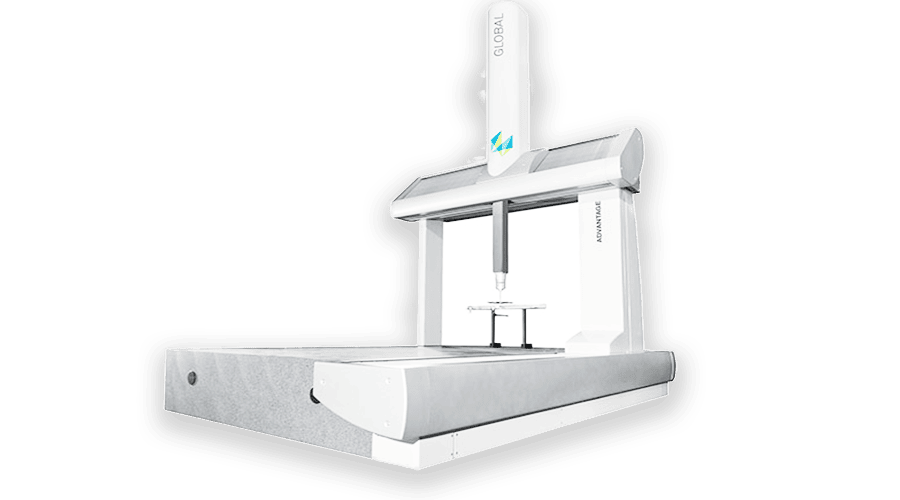

CMM HEXAGON

This equipment measures critical CNC product parts in terms of X, Y and Z axes. With its 3 axis, the component is measured precisely on all sides. This operation gives a clear overview of dimensions. Often, it is the tolerances that are not respected or the shape of the part that is not appropriated.