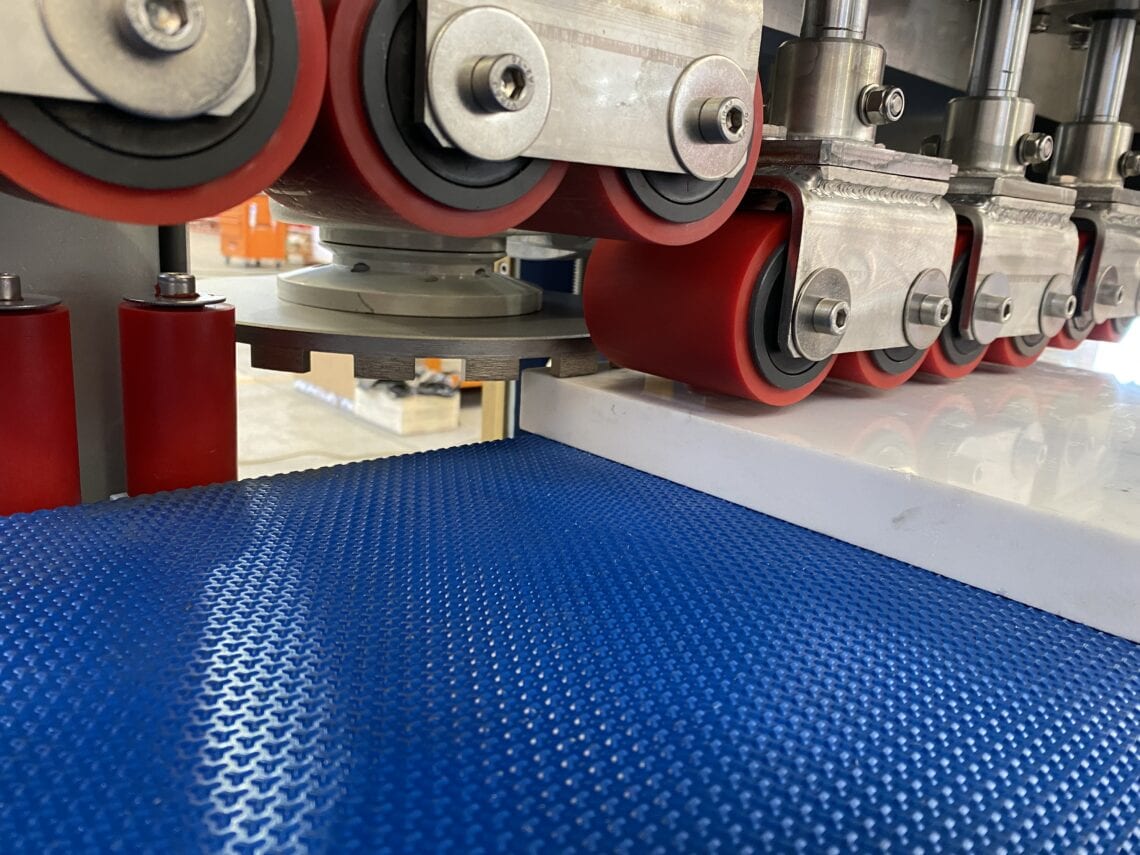

Edge polishing

machines

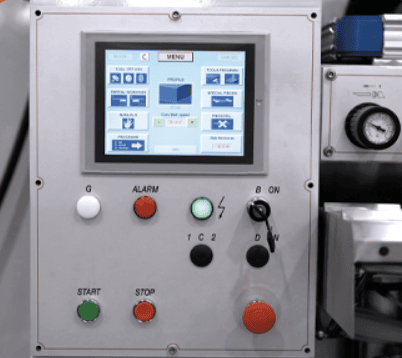

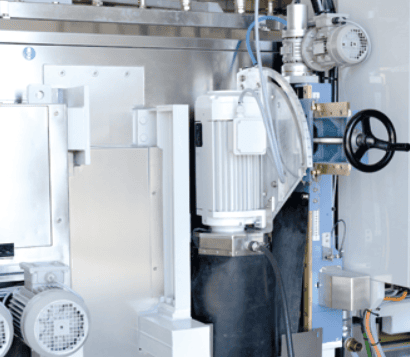

Our partnership with Comandulli

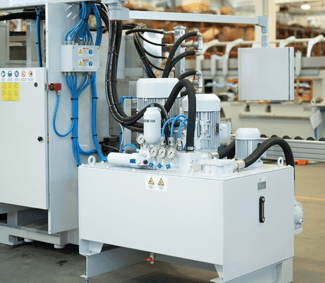

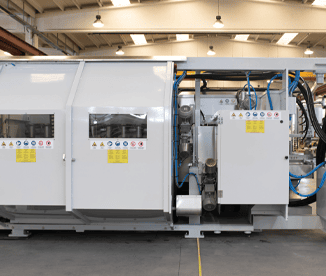

Mec precision is the Canadian distributor and authorized service center of Comandulli. We have the privilege to access the edge polishing machine distribution line. Moreover, we can repair, maintain and install all products. Every repair is done by following the quality standards established by the manufacturer. If you are interested in acquiring a Comandulli machine, we will be able to help and assist you rapidly.

Comandulli

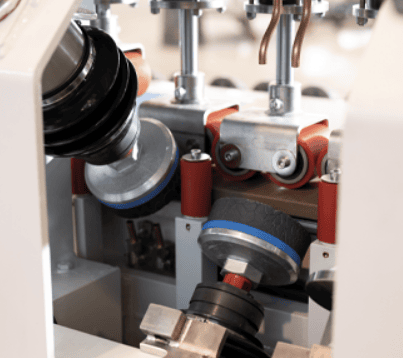

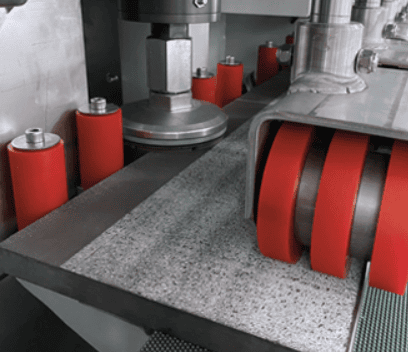

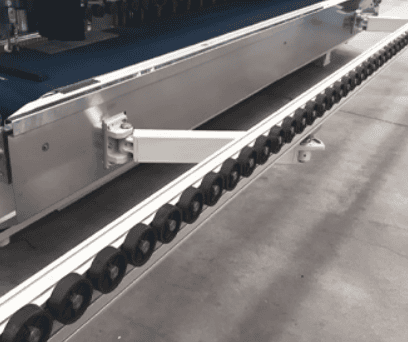

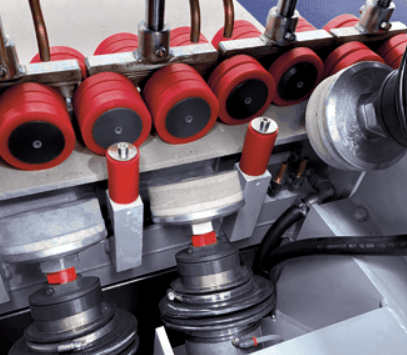

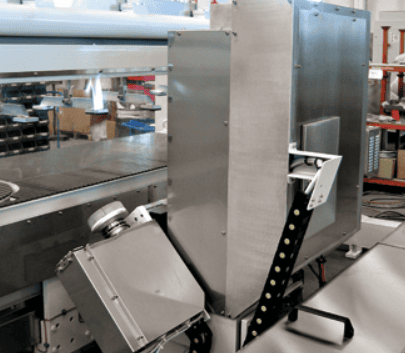

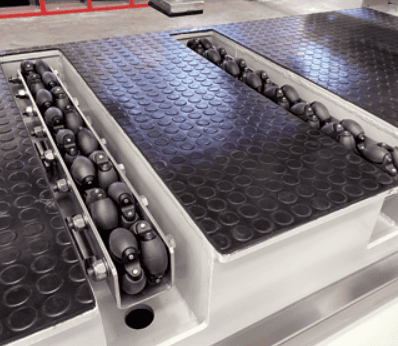

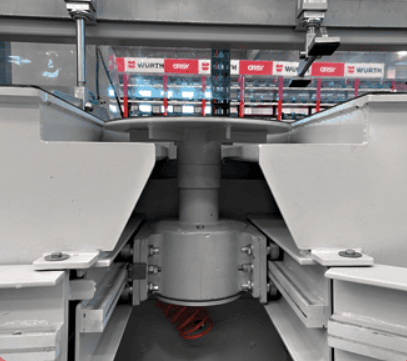

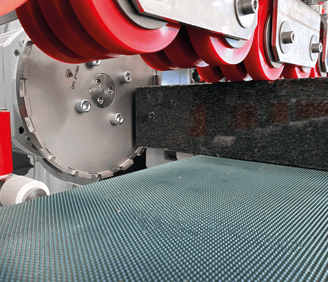

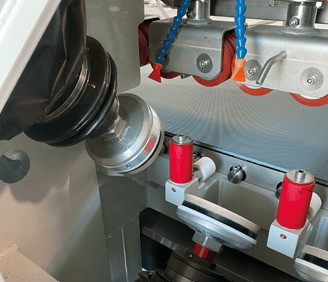

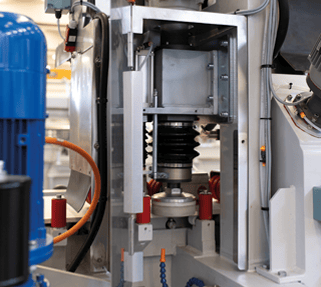

For many years, Comandulli has been a leader in the design and manufacturing of high technology edge polishing machines for the CNC industry. Their equipments are renowed for their performance in term of precision and durability. They are mainly used in the stone and marble industries.

Need more information on Comandulli

machines ?

Talk with our technical advisors now.

Products range

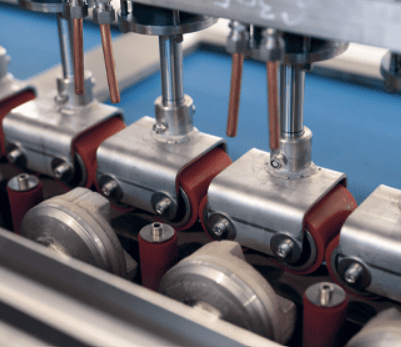

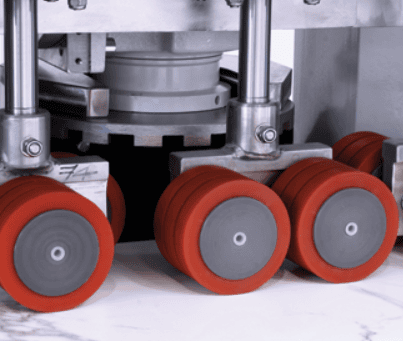

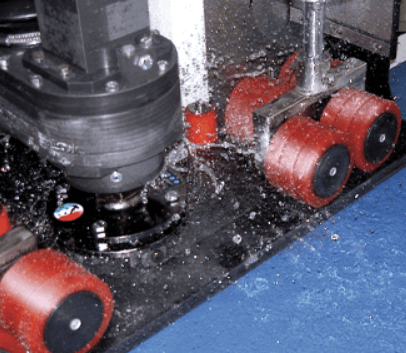

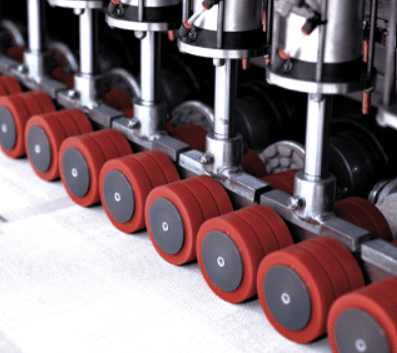

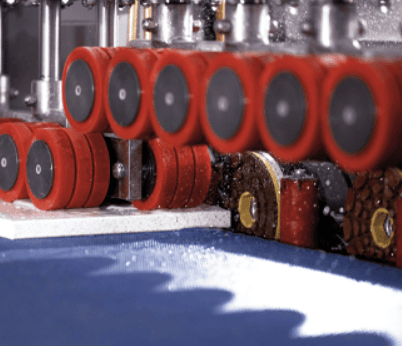

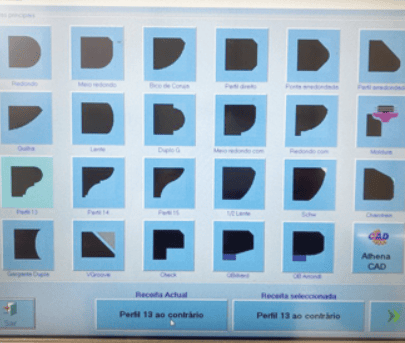

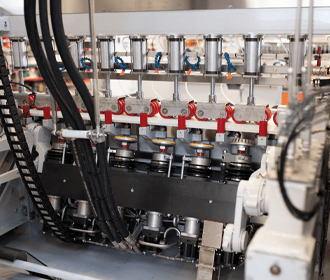

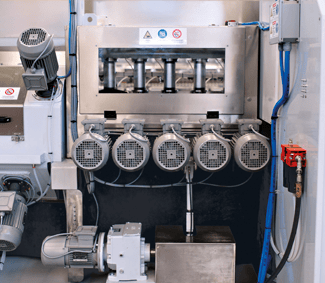

Comandulli has a wide range of innovative products covering machines specialized for edge polishing. They are available in many sectors such as furnishing, building and monument under several models like Athena, Penta and Musa etc. These machines can polish rounded, straight, upper grooves and calibrated edges etc.

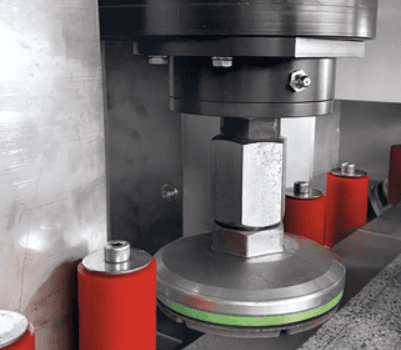

Authorized service center of Comandulli

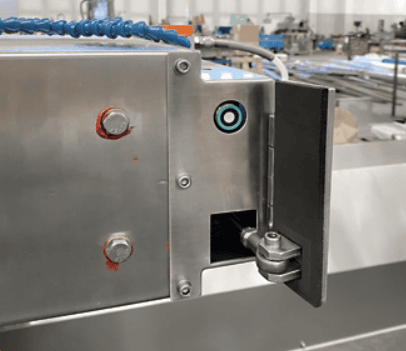

As the authorized service center, we are able to repair, install and maintain all products of this manufacturer. We have most of the OEM parts in inventory and our technicians are certified by Comandulli. Every product goes through a rigourous and quality rebuild process. Each one is analysed, fixed and tested by our technicians at your workshop.

Learn moreOur catalog

Application

Small shop

Work speed

1÷3 cm = 50÷60 cm/min

Specifications

Thickness : 1+6 cm

Min Width : 8 cm

5 heads for the edge

4 heads (2+2) for the 45e bevel

Min Width : 8 cm

5 heads for the edge

4 heads (2+2) for the 45e bevel

Options available

Calibrating unit (entry)

Cutting unit (exit)

Vertical spindle (exit)

Cutting unit (exit)

Vertical spindle (exit)

Application

Small-Medium shop furnishing and buildings.

Work speed

1÷3 cm = 50÷60 cm/min

Specifications

Thickness : 1+8 cm

Min Width : 6 or 8 cm

7 heads for the edge

4 heads (2+2) for the 45e bevel

Min Width : 6 or 8 cm

7 heads for the edge

4 heads (2+2) for the 45e bevel

Options available

Calibrating unit (entry)

Cutting unit (exit)

Vertical spindle (exit)

Cutting unit (exit)

Vertical spindle (exit)

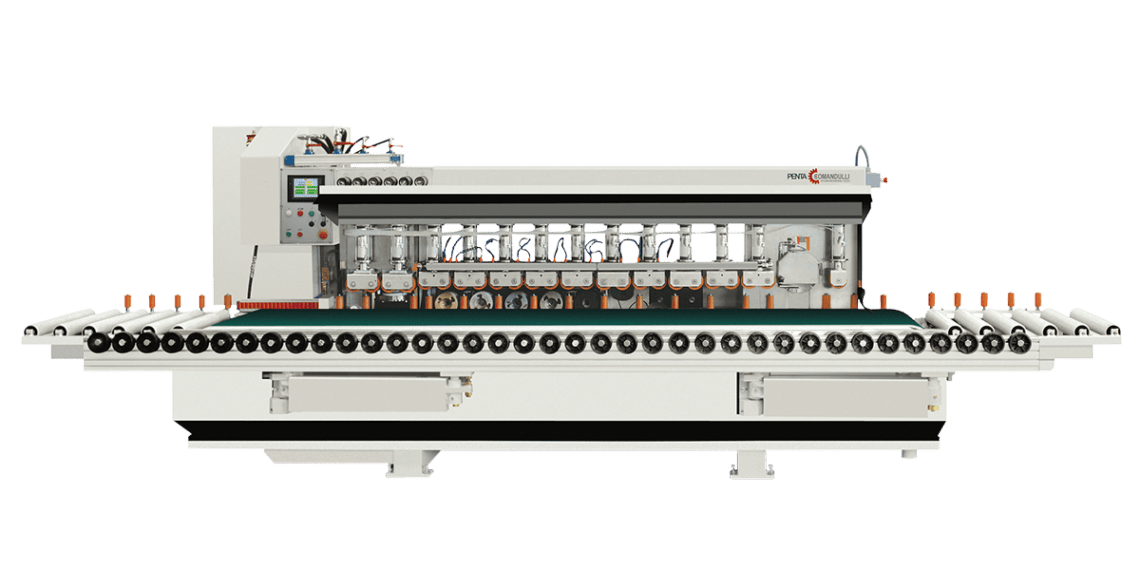

Application

High production furnishing and design.

Work speed

1÷3 cm = 60÷80 cm/min

Specifications

Thickness : 0.6÷8 cm

Min Width : 6 cm

8 heads for the edge

2 heads with diamond (calibrated bevel)

4 heads (2+2) for the 45e bevel

Min Width : 6 cm

8 heads for the edge

2 heads with diamond (calibrated bevel)

4 heads (2+2) for the 45e bevel

Options available

Calibrating unit (entry)

Cutting unit (exit)

Vertical spindle (exit)

Cutting unit (exit)

Vertical spindle (exit)

Application

Small series and many profiles.

Work speed

?

Specifications

Thickness : 1+12 cm

Min Width : 10 cm

1 spindle (mono head)

Automatic tool magazine 8 positions

Min Width : 10 cm

1 spindle (mono head)

Automatic tool magazine 8 positions

Options available

Cutting disc (Take 2 positions of the tool magazine) Max 3 cm thickness

Application

Small series, all profiles and monument.

Work speed

?

Specifications

Thickness flat edge : 1+35 cm

Thickness shaped edge: 1+25 cm

Min Width : 10 cm

1 spindle (mono head)

Automatic tool magazine 12 positions

Thickness shaped edge: 1+25 cm

Min Width : 10 cm

1 spindle (mono head)

Automatic tool magazine 12 positions

Options available

Cutting disc (Take 2 positions of the tool magazine) Max 3 cm thickness

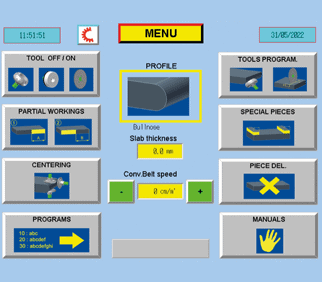

Application

High production furnishing, building and monument.

Work speed

Bullnose: 1÷3 cm = 20÷30 cm/min

Pencil round : 1÷3 cm = 17 cm/min

Flat edge : 1÷3 = 70÷80 cm/min

Pencil round : 1÷3 cm = 17 cm/min

Flat edge : 1÷3 = 70÷80 cm/min

Specifications

Thickness: 1+10 cm

Min Width: 20 cm

1 calibrating unit (entry)

Pregringing units (1 upper + 1lower)

8 heads on oscillating beam to profile

4 heads (2+2) for the 45e bevel

Min Width: 20 cm

1 calibrating unit (entry)

Pregringing units (1 upper + 1lower)

8 heads on oscillating beam to profile

4 heads (2+2) for the 45e bevel

Options available

Cutting unit (exit)

Vertical spindle (exit)

TMM device for the calibrated bevel

Vertical spindle (exit)

TMM device for the calibrated bevel

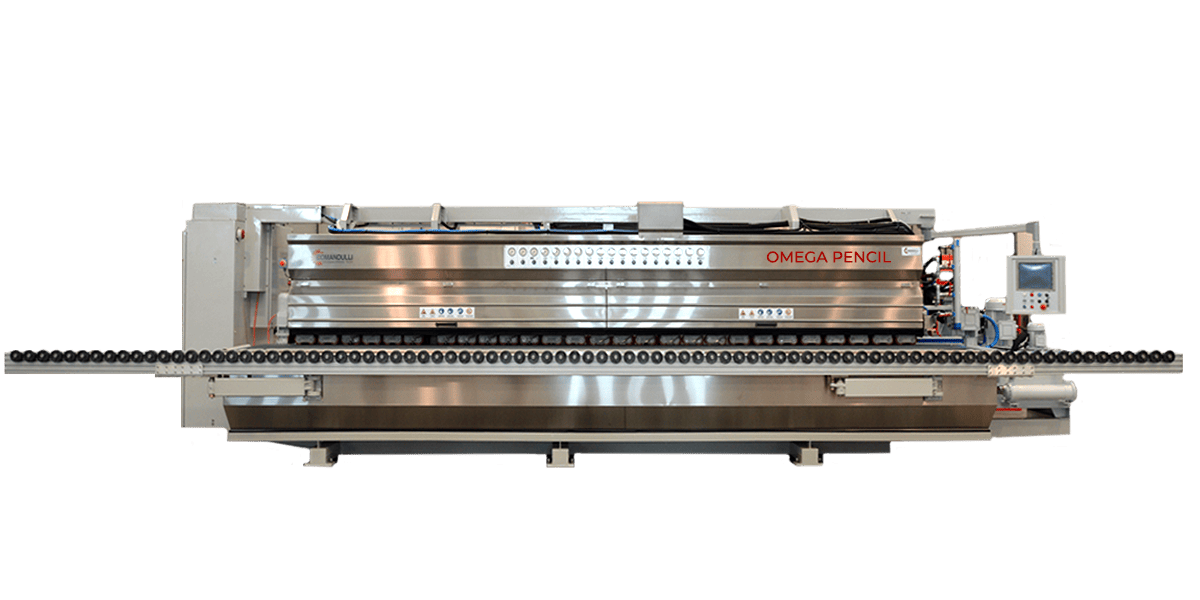

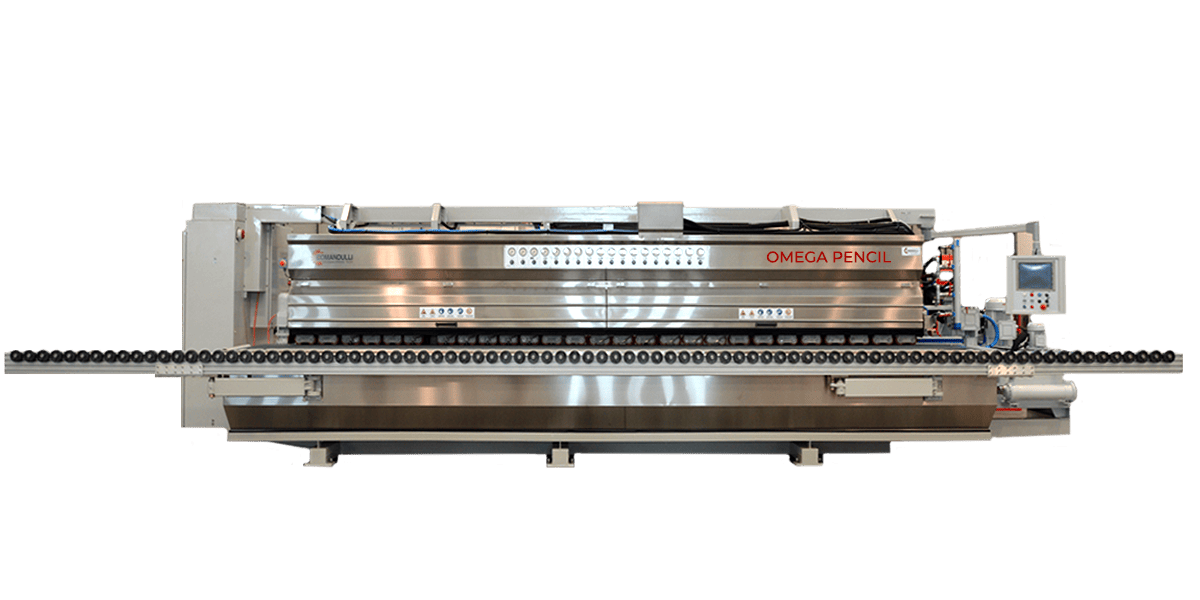

Application

High production furnishing.

Work speed

Bullnose: 1÷3 cm = 20÷30 cm/min

Pencil round : 1÷3 cm = 70 cm/min

Flat edge : 1÷3 = 80÷100 cm/min

Pencil round : 1÷3 cm = 70 cm/min

Flat edge : 1÷3 = 80÷100 cm/min

Specifications

Thickness: 1+6 cm

Min Width: 20 cm

Calibrating + rectifying group (entry)

Pregringing units (1 upper + 1 lower)

6 heads on oscillating beam to profile

5 heads fixed, to polish the edge

4 heads (2+2) for the 45e bevel

Min Width: 20 cm

Calibrating + rectifying group (entry)

Pregringing units (1 upper + 1 lower)

6 heads on oscillating beam to profile

5 heads fixed, to polish the edge

4 heads (2+2) for the 45e bevel

Options available

Vertical spindle (exit)

TMM device for the calibrated bevel

TMM device for the calibrated bevel

Application

High production furnishing.

Work speed

Bullnose: 1÷3 cm = 20÷30 cm/min

Pencil round : 1÷3 cm = 70 cm/min

Flat edge : 1÷3 = 80÷100 cm/min

Pencil round : 1÷3 cm = 70 cm/min

Flat edge : 1÷3 = 80÷100 cm/min

Specifications

Thickness: 1+6 cm

Min Width: 20 cm

Calibrating + rectifying group (entry)

Pregringing units (1 upper + 1 lower)

6 heads on oscillating beam to profile

5 heads fixed, to polish the edge

Min Width: 20 cm

Calibrating + rectifying group (entry)

Pregringing units (1 upper + 1 lower)

6 heads on oscillating beam to profile

5 heads fixed, to polish the edge

Options available

Vertical spindle (exit)