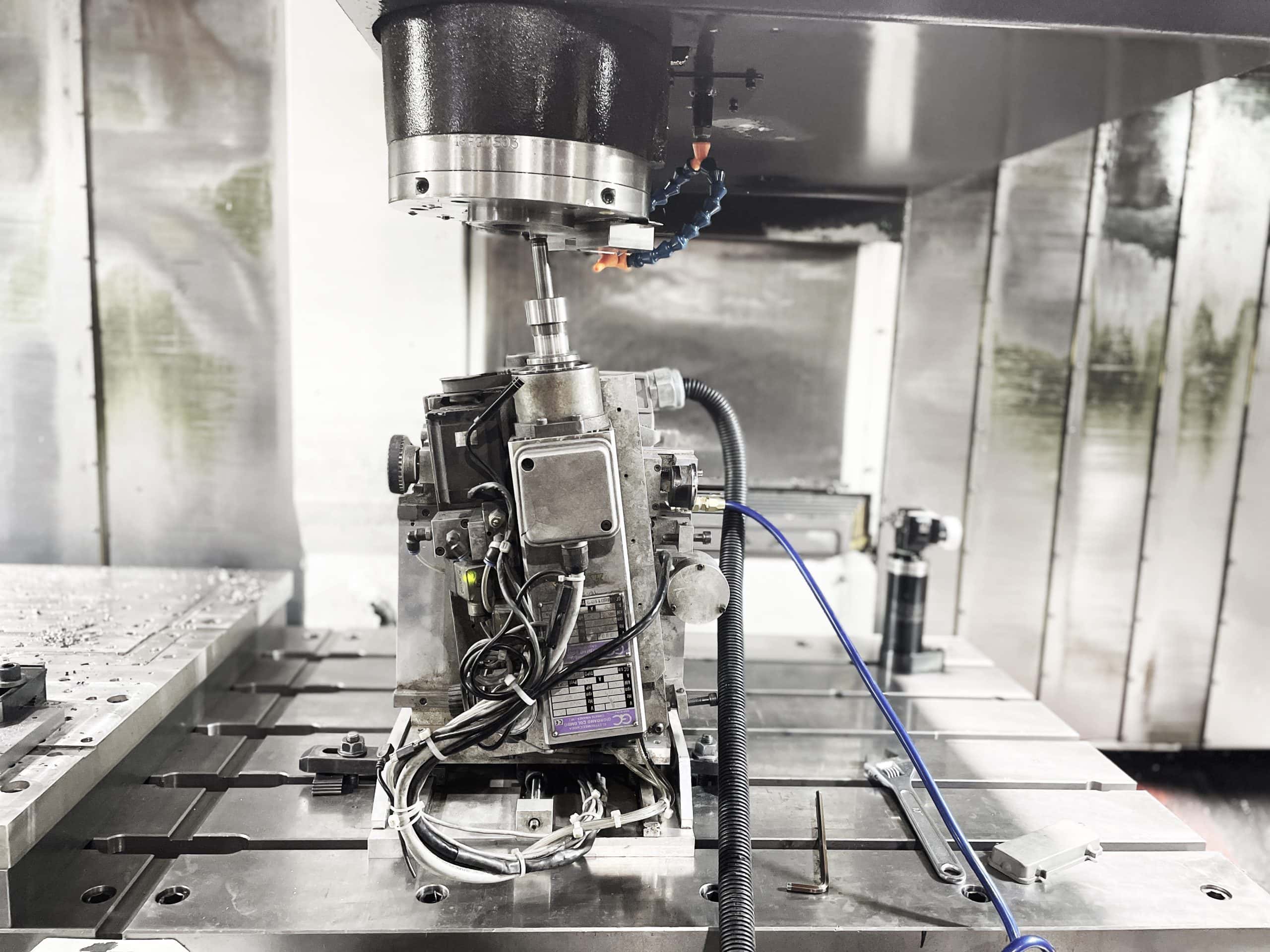

The spindle taper is a critical part that has a key role in the machining of materials. Indeed, this component ensures the upkeep and positioning of the toolholder as well as the tool position towards the work material. Therefore, the taper condition directly affects the precision level and workflow of the machining operation. For this reason, it is important to clean and maintain the taper on a regular basis!

What happens if the taper surface is damaged?! Multiple problems can be occurred:

- The contact surface between the tool and toolholder is decreasing. This issue significantly reduces the precision of machining.

- The toolholder position will no longer be straight. Due to this, the CNC machine can shut down.

- The level of vibration can increase so its impacts the durability of the spindle bearings.

- The toolholder and tool can become damaged. By replacing them frequently there the cost at the end is expensive.

All these problems can be avoided if the taper is cleaned and maintained. What are the best practices to implement?

Here what you can do :

- Clean the taper surface and the toolholder with a maintenance tool specially designed for them. How to proceed ? Insert the tool in the taper and turn it to wash the inside.

-

Ideally, this process needs to be done periodically. Lucky you! We have this product in our inventory. If you don’t have it, get yours now at info@mec-precision.com.

Ideally, this process needs to be done periodically. Lucky you! We have this product in our inventory. If you don’t have it, get yours now at info@mec-precision.com.

- Verify the taper surface performing a blue test. First, put the liquid on the toolholder and insert it into the taper. Be sure to embed properly the toolholder so that the liquid impregnates the taper surface. Once complete, remove the toolholder. Inspect the surface of the toolholder as well as the taper. If both area are all in blue, the taper condition is good. If the contrary, it needs to be ground.

-

By inspecting and ensuring the cleanliness of the taper, you will have a constant machining precision. Therefore, a good positioning of the tool and the tool holder. Also, a low level of bearing vibration and reduced downtime.

By inspecting and ensuring the cleanliness of the taper, you will have a constant machining precision. Therefore, a good positioning of the tool and the tool holder. Also, a low level of bearing vibration and reduced downtime.

Our taper grinding solution

In case the taper surface presents damage, use our taper grind solution. Our technicians are qualified to inspect the state of the taper and grind it according to manufacturing specifications on your CNC machine. Contact us at info@mec-precision.com.